Computer Aided Design, Development & Performance Evaluation of a Model Solar Powered Electric Vehicle

This dissertation focuses on the design and development of an innovative solar-powered electric vehicle (EV). Using computational tools such as Computer-Aided Design (CAD), Computational Fluid Dynamics (CFD), and real-world testing, the research aims to improve the efficiency of electric vehicles by integrating solar panels and improving aerodynamic performance. The objective is to extend the driving range of EVs and contribute to the shift toward renewable energy sources, helping mitigate climate change by reducing reliance on fossil fuels.

Introduction

The motivation for this research arises from the pressing need to address climate change, as the transportation sector's dependence on fossil fuels is a major contributor to carbon dioxide (CO₂) emissions. Electric vehicles (EVs) are increasingly recognized as a crucial element in the solution to this problem, with the integration of solar energy offering a promising innovation to further extend vehicle range and efficiency. As the UK moves toward a ban on the sale of petrol and diesel vehicles by 2030, solar panels present an on-the-go charging solution akin to regenerative braking, reducing the need for external charging infrastructure and enhancing the sustainability of EVs.

Objectives

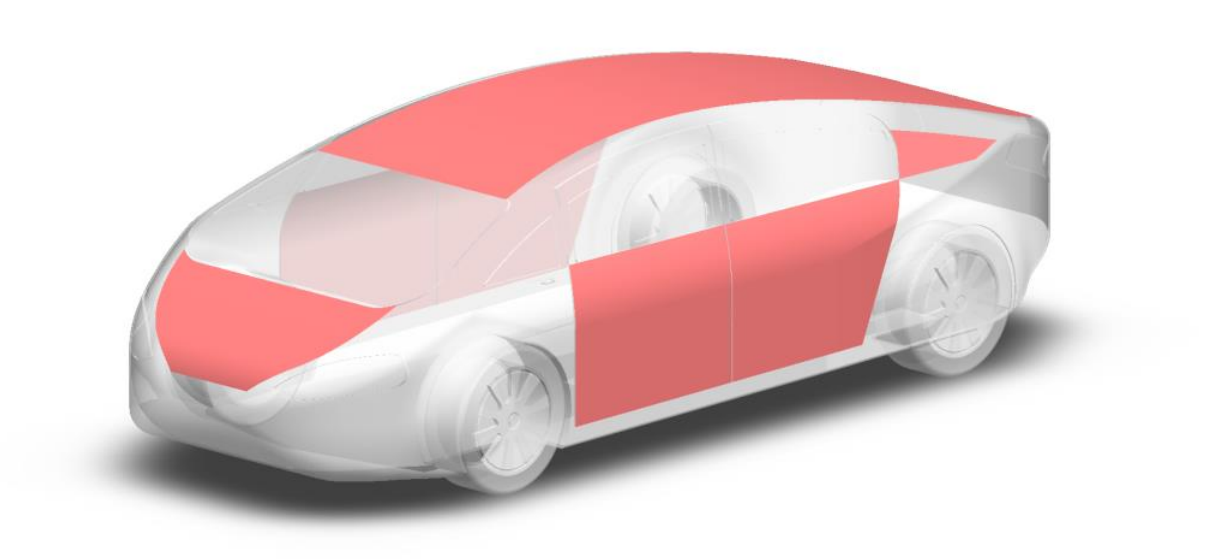

The main goal of this study is to design an aerodynamic efficient body for an EV and incorporating solar panels on the roof, hood, and doors. This integration aims to provide an on-the-go charging solution while respecting the current limitations of solar panel curvature. Additionally, the new design seeks to reduce the drag coefficient (Cd) and ensure that the vehicle generates downforce rather than lift (Cl), thereby improving aerodynamic performance.

The design and development process involved the use of SolidWorks for CAD modeling and Ansys Fluent for CFD simulations. The design process was iterative, with improvements made based on evaluations of aerodynamic performance.

Methodology

CAD and 3D Modelling

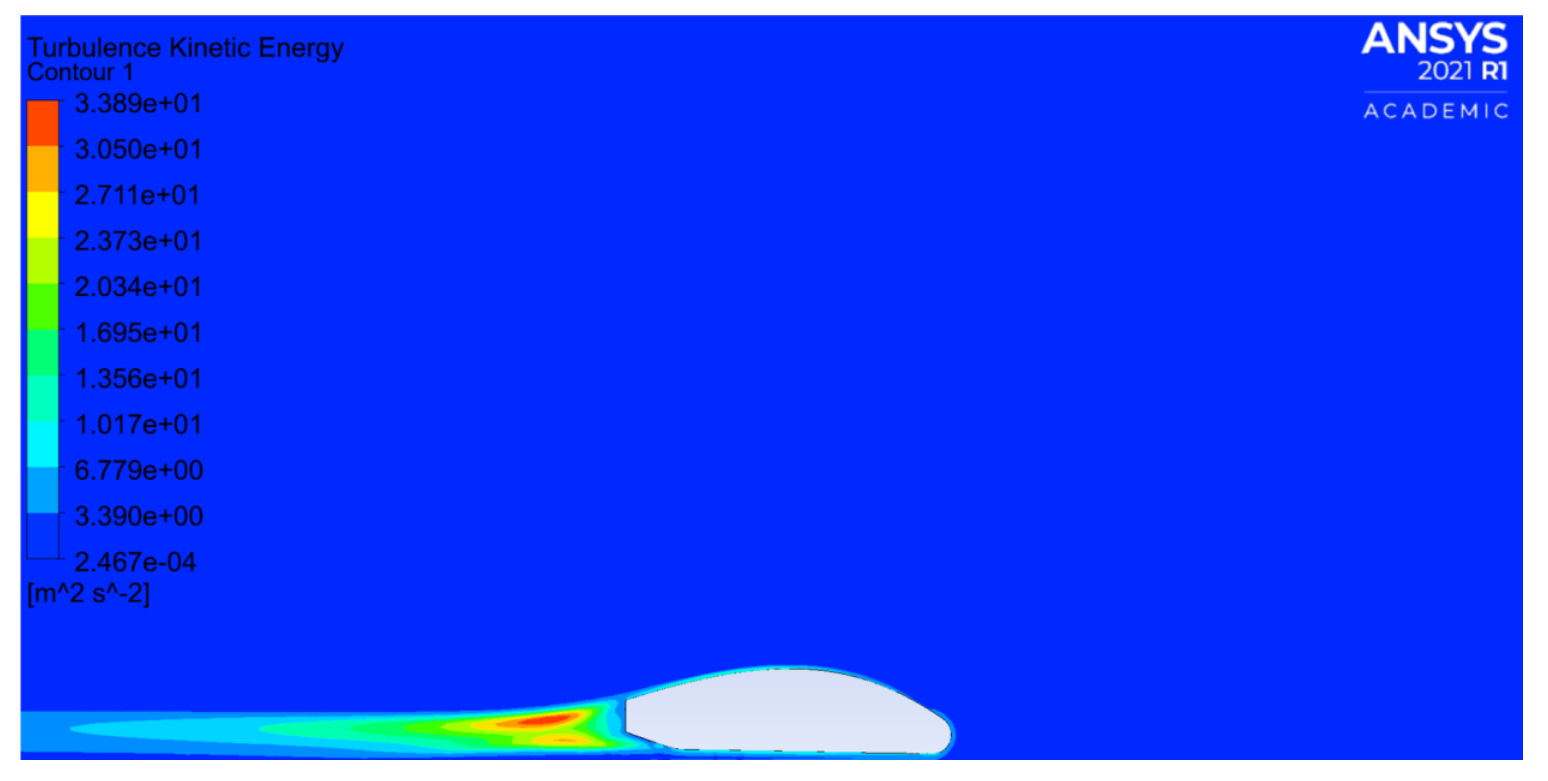

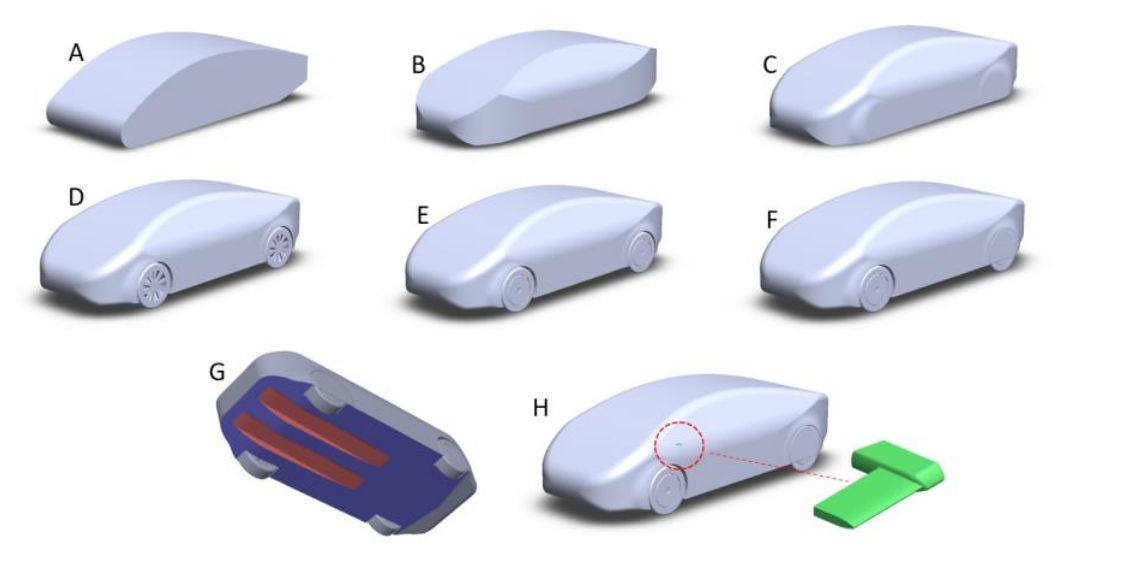

The initial designs were based on the exterior dimensions of the Tesla Model S, serving as the baseline for the new design. The goal was to maintain the vehicle's overall dimensions while improving aerodynamics and integrating solar panels. During this stage, three 2D shapes were created and evaluated for their drag and lift coefficients. The selected shape, exhibited the best aerodynamic performance, producing downforce with a low drag coefficient (Cd = 0.189, Cl = -0.501).

The 3D model development proceeded through eight iterations, starting from basic extrusions to more refined designs. Each iteration aimed to reduce drag while ensuring the vehicle maintained downforce. Among the final designs, Model G, which included an underbody diffuser, demonstrated the best aerodynamic performance by reducing both drag (Cd = 0.197) and lift (Cl = -0.021). The final concept, Model H, introduced futuristic design elements that further improved performance.

3D Print & Wind Tunnel Testing

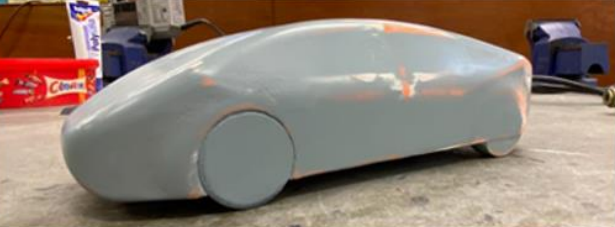

The 3D model of the redesigned vehicle (Model H) was scaled down to 1/16 of its original size and 3D printed for wind tunnel testing. To achieve a smooth finish, the model underwent multiple rounds of filler application, sanding, and two layers of primer with wet sanding in between. Pressure tap holes were drilled into the model for testing.

In the wind tunnel, the model was positioned on a table simulating a road, allowing for limited movement. However, the wind tunnel results for drag (Cd) and lift (Cl) coefficients showed discrepancies of 42% and 68%, respectively, when compared to CFD simulations. These differences were attributed to limitations in the wind tunnel setup, including constraints on pitch and yaw adjustments, potential misalignment of the model, and the impact of the model's supporting arms on airflow. Despite these issues, a smoke test indicated that the vehicle's airflow was streamlined with no major separation.

Additionally, a pressure tapping test was conducted at 11 points on the model, yielding results within 19% of the CFD predictions. This test was more accurate as it did not involve the problematic arms, and alignment was done manually.

Solar Panel Experiment

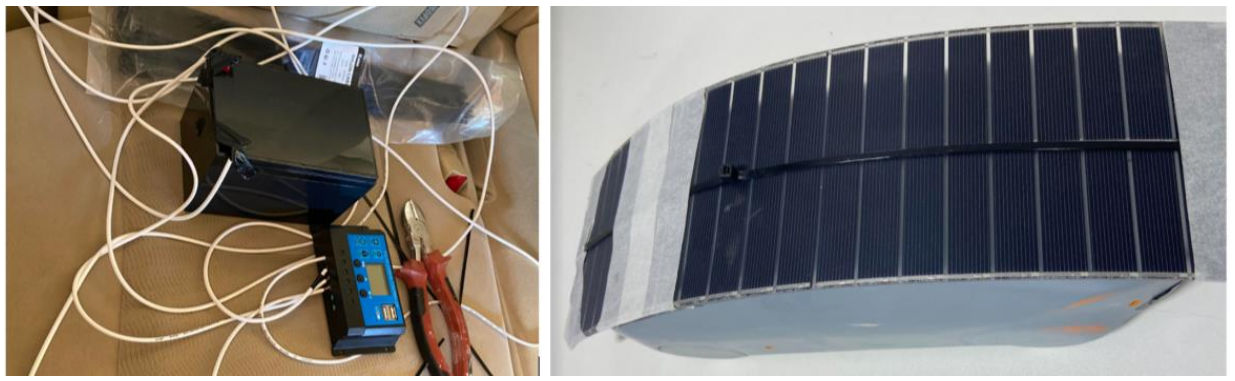

A solar power experiment was conducted on a scaled-down 3D model of the redesigned vehicle in Saudi Arabia. The setup included a 12V flexible solar panel, a charge controller, and a 12V lead-acid battery representing 38% of a scaled-down Tesla Model S battery.

Over four days, the model was driven for two hours daily, with the battery's voltage steadily increasing each day from 11.96V to 12.52V. The experiment demonstrated that the solar system charged the battery to about 88%, translating to a 33.8% increase in charge. When scaled to a full-size vehicle, this would equate to an additional 135.2 miles (217.6 km) of driving range.

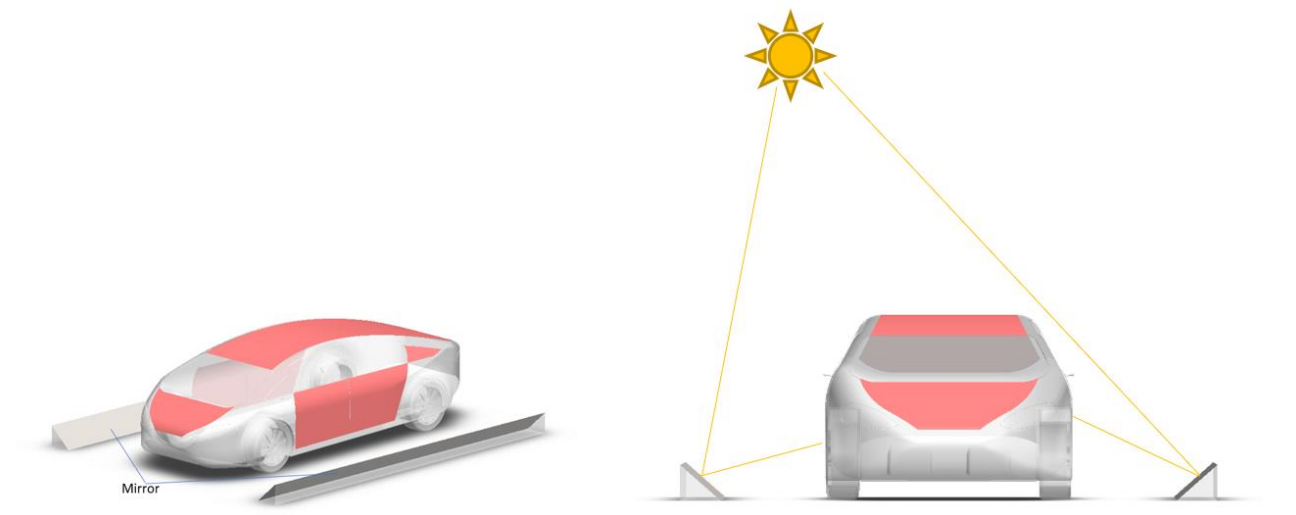

Solar Parking Mirrors

A design concept for maximizing solar energy output from both sides of a vehicle involves using concentrated solar photovoltaics (CSPV) with mirrors placed on the sides of a parking space. These mirrors reflect sunlight onto the side panels of the vehicle throughout the day, ensuring both sides receive sunlight even when one side is in shade. This method can increase the energy output of the solar panels by up to 30.89%, as reflected light enhances sunlight exposure. In specific examples, such as in Riyadh, this setup increased total energy output by 21.69%, resulting in more range for the vehicle. Without parking mirrors, the vehicle gains substantial free energy; however, using mirrors further increases this benefit when the vehicle is stationary.